Continuous Casting

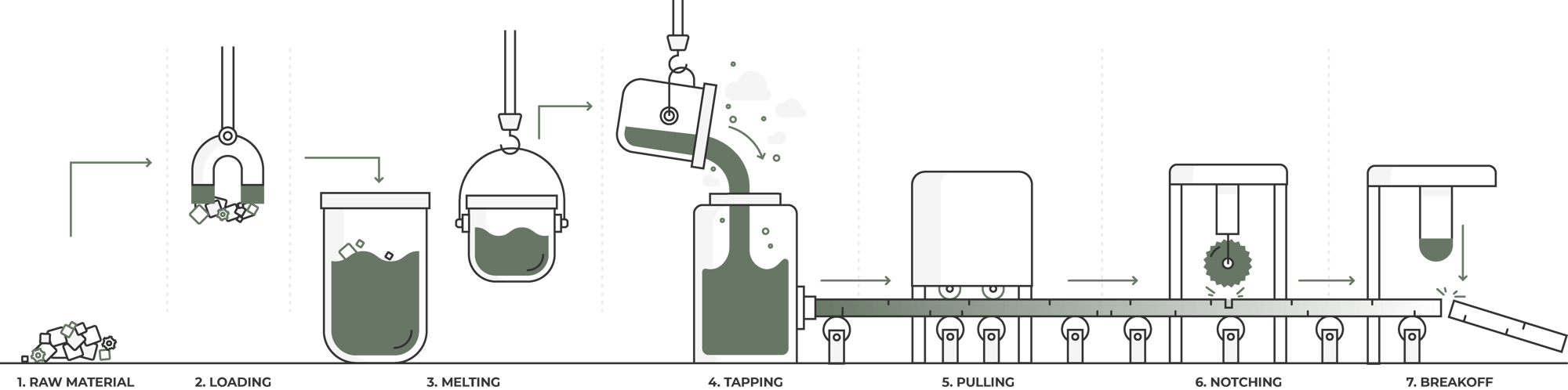

The Continuous Casting Process

TASSO's continuous cast iron bars are made from recycled steel scrap and pig iron. Before casting, the molten iron undergoes a careful preparation process of chemical analysis and adjustment to meet the requirements for the final cast iron bar. Continuous cast material is produced from a melt in the form of an (in theory) infinitely long cast iron bar in either grey (GJL) or ductile iron (GJS).

Continuous casting is a casting method, in which the steps of pouring, solidification and drawing of casting from an open-end mould are carried out continuously. When the liquid iron passes through the water-cooled mould, it solidifies as a profile which is determined by the shape of the mould. When the bar leaves the open-ended die, it has not yet solidified all the way through; the core of the bar remains molten. The entire bar then cools in the air until the drawing station pulls the solidified material forward in a series of steps, and the bar is then cut into standard lengths.

Homogenous and uniform microstructure

At TASSO we are highly aware of running a secure process with a minimum of fluctuations to ensure uniformity in the cast iron bars. The most significant characteristic of TASSO continuous cast iron is its homogeneous, fine-grained, dense, as-cast microstructure which is cavity- and pore free. The consistency of TASSO material stems from the continuous casting process. The casting process involves pulling the bars through a graphite die at the bottom of the holding crucible filled with molten iron. Slag and other impurities float to top of the crucible/holding unit, away from the opening of the die and will therefore never make it into the bars.

The fine-grained structure allows faster machining, wear resistance, extended tool life, and good mechanical properties of the material. These characteristics combined with various dimensions and shapes in round, square and rectangular is what make TassoBar continuous cast iron a high performing and economic materials, which creates value across a wide range of industries.

VALUE TO YOUR COMPONENT PARTS

Advantages of cast iron

Continuous cast iron bars from TASSO offers numerous structural and physical advantages over other materials such as steel, aluminium and sand castings because of the unique manufacturing methods of continuous casting.

CONTACT

Let's help you choosing the right cast iron material grade for your next project.

Henrik Elmkvist, Commercial Director

Let's talk